Luview Forklift Camera System: The Visual Solution for Efficient and Safe Operations

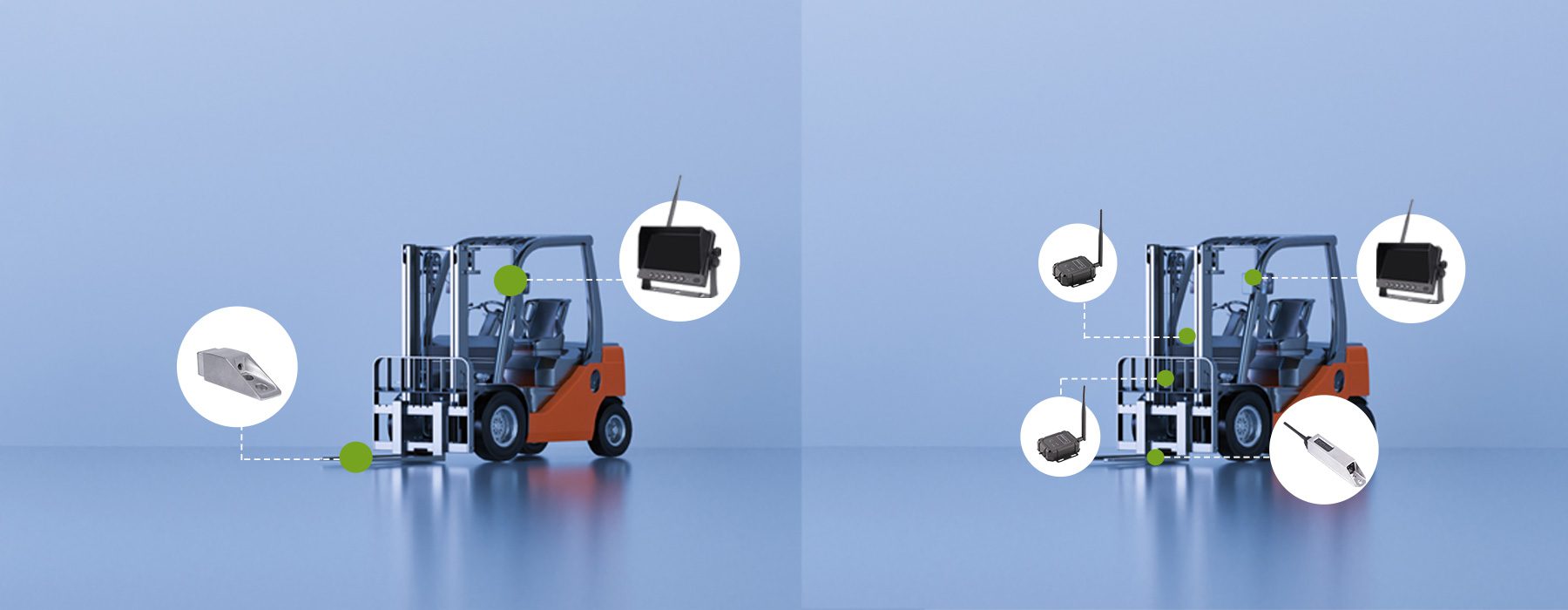

As a professional provider of forklift camera systems, Luview is committed to delivering high-performance, high-reliability wireless magnetic forklift camera solutions, redefining operational efficiency and safety standards for forklift operators. Our forklift monitoring systems cover a range of product lines including the JY-M176W+JY-F5 and JY-M176+RX03+F6+TX03 series, which are tailor-made for medium and large-sized forklifts, automated guided forklifts, and complex operation scenarios, fully meeting diverse application needs.

I.Core Product Advantages

1. Wireless Magnetic Mounting

The JY-F5 wireless camera features a magnetic structure design, enabling tool-free installation and flexible repositioning. This design not only streamlines the deployment process but also minimizes equipment damage in the event of accidental collisions. The system is seamlessly compatible with various forklift models while ensuring structural stability.

2. High-Definition Image Quality

Superior HD viewing experience: The JY-M176W+JY-F5 system is equipped with a 1/2.9-inch CMOS sensor, supporting 720P resolution for real-time transmission of clear images. The JY-M176+RX03+F6+TX03 system comes with a 2-megapixel 1/3-inch SC2336 sensor, supporting 1080P full HD output and progressive scan technology, which delivers sharp and stable images even during dynamic operations.

3. Waterproof & Durable

All Luview forklift monitoring systems achieve an IP68 waterproof rating, ensuring stable operation in rainy weather and harsh industrial environments. The cameras adopt a metal casing design, boasting high strength, impact resistance, and wear resistance for an extended service life.

4. Low-Light Adaptability

The JY-F5 camera has a minimum illumination of only 0.1 lux, while the F6 camera has a minimum illumination of 1 lux. Combined with automatic gain control and auto white balance functions, the cameras ensure clear visibility and consistent image quality even in dimly lit warehouses or night-time operating scenarios.

5. Intelligent Function Configuration

Auxiliary Positioning Function: The Luview wireless forklift system supports auxiliary positioning (requires a dedicated monitor), helping operators precisely align the forks with pallets or shelves, reducing loading and unloading errors, and significantly improving operational efficiency.

6. Long-Distance Wireless Transmission

The system offers a wireless connection range of up to 30 meters in open environments, with stable signal and smooth image transmission. It completely eliminates the constraints of wired connections, enabling flexible camera layout.

7. Multi-Channel Monitoring Capability

The JY-M176W 7-inch color display supports multi-channel input, allowing simultaneous installation of multiple cameras. It provides full coverage of the forklift’s front, rear, and blind spots, enhancing the operator’s environmental awareness.

II. Customized OEM Cooperation Solutions

Luview provides exclusive OEM cooperation services for global forklift manufacturers (including OEM partners in Germany, Europe, America, and other regions), with three core pillars:

1. Customized Product Development

We tailor-make camera systems based on customers’ specific forklift models and functional requirements, ensuring seamless integration with the vehicle to enhance the overall brand recognition of the complete machine.

2. Full-Process Technical Support

Our professional R&D team offers end-to-end technical support covering product design, sample testing, production line assembly guidance, and after-sales maintenance. This empowers OEM partners to accelerate product certification and mass production processes efficiently.

3. Stable Supply Chain & Quality Assurance

Luview operates its own manufacturing facilities in Shenzhen, China, and Malaysia, boasting a complete supply chain system and large-scale production capacity to guarantee on-time delivery of bulk orders. All products strictly comply with ISO9001/ISO45000/VDA6.3 quality standards. Rigorous quality control measures are implemented throughout every stage—from raw material procurement and production processing to finished product inspection—ensuring consistent product quality and reliability.

Are you plagued by these pain points in forklift operation scenarios?

1. Blind Spot Hazards

Forklift operations involve multiple blind spots. When loading/unloading goods, navigating narrow aisles, or turning to meet other vehicles, do you constantly worry about collisions with pedestrians, scratches to goods or equipment, and persistent safety risks in the factory premises?

2. Inflexible & Outdated Equipment

Are your existing operation monitoring devices limited to single functions, unable to adapt to multi-scenario operational needs? As enterprises advance toward intelligent upgrading, can these devices fail to meet requirements for equipment linkage and data transmission, resulting in high costs and low efficiency due to frequent device replacements?

3. Inefficient After-Sales Service

After equipment malfunctions, do delayed after-sales responses and inadequate technical support lead to operational interruptions, production halts, escalating losses, and a subpar cooperation experience?

4. Low Operational Precision

Due to restricted visibility, do operators need to repeatedly adjust the forklift when picking up goods or docking with trailers? This not only slows down operational progress but also increases equipment wear and labor costs.

Why Choose Luview Forklift Camera Systems?

Exclusive OEM Cooperation Solutions

To better serve forklift OEMs and manufacturers worldwide, Luview offers a full-process cooperation solution from product customization, technical support to batch delivery, ensuring efficient and smooth cooperation.

1. Customized product development

Based on the forklift model design and functional requirements of the OEM manufacturer, we provide personalized customization services to ensure the perfect integration of the product with the forklift and enhance the brand recognition of the entire vehicle.

2. Full-process technical support

We have a professional RD team that provides full-process technical support from product design, sample testing, production line assembly guidance to after-sales maintenance, helping OEM manufacturers quickly complete product certification and mass production.

3. Stable supply chain and batch delivery

With a complete supply chain system and large-scale production capacity, it can ensure the stable delivery of bulk orders. Establish a strict quality control system. From raw material procurement, production processing to finished product inspection, every link complies with 1s09001/1s045000/VDA6.3 quality standards to ensure product consistency and reliability.

FAQ

Q1: What Components Does the Luview Forklift Camera Monitoring System Consist Of?

The complete system is mainly composed of core components such as forklift cameras, rear-view cameras, and 7-inch LCD monitors. Its core function is to eliminate visual blind spots during forklift travel and operation. It assists operators in clearly observing the surrounding environment in real time for scenarios like aisle navigation, cargo trailer docking, and goods lifting. This effectively mitigates safety risks such as pedestrian collisions and cargo scratches, while improving operational accuracy and efficiency and reducing economic losses caused by equipment damage.

Q2: What Are the Main Factors Determining the Price Differences of Products?

Price differences are mainly determined by system models and functional configurations. For example, features including multi-camera linkage, video recording and storage support, night vision performance levels, and protection ratings will all affect the final pricing.

Q3: What If the Monitor Suffers from Glare and Becomes Unreadable?

The monitors provided by Luview are equipped with sun visors, which can effectively prevent the screen from being exposed to direct sunlight or strong light sources and reduce glare interference.

Q4: How to Install the Forklift Camera?

Our forklift cameras adopt a magnetic structure, enabling extremely convenient installation and disassembly. For installation, simply attach the camera directly to the forklift body.